Simulation on Jaguar shows potential for cheaper, more efficient carbon capture. Visualization by Mike Matheson (ORNL).

Simulation on Jaguar shows potential for cheaper, more efficient carbon capture

One of the most pressing scientific challenges facing the United States and the world is reducing greenhouse gas emissions. Compounding that challenge is the fact that power plants burning fossil fuels account for more than 40 percent of the world’s energy-related CO2 emissions and will continue to dominate the supply of electricity until the middle of the century. There is an urgent need for cost-effective methods to capture and store their carbon emissions.

The Department of Energy (DOE) is currently sponsoring large-scale demonstration projects to prove the viability of carbon capture and sequestration (CCS). The principal barrier to widespread application of CCS is its cost. Once the CO2 is captured, compressing it to the required 100 atmospheres represents approximately 33 percent of the total cost of CCS.

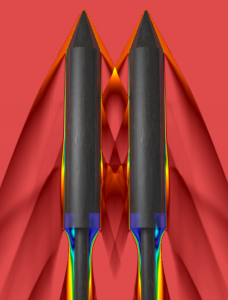

Ramgen Power Systems is using Jaguar to simulate equipment that will achieve carbon sequestration at a significantly lower cost than that offered by conventional equipment. This image is the high-resolution result of a billion-cell two-body simulation showing the complex reflected structures colored by mach number. Visualization by Mike Matheson, ORNL.

Ramgen Power Systems, a small, Seattle-based energy research and development (R&D) firm, is developing a novel gas compressor system based on shock-wave technology used in supersonic flight applications. This technology holds important promise for the turbomachinery industry of engines and compressors. Ramgen is a world leader in applying this shock-wave-based compression technique to gases, including CO2—a more challenging application than air because of CO2’s larger molecular weight. DOE’s National Energy Technology Laboratory is providing cost-shared support for this project.

The traditional process to design and optimize new turbomachinery, or machines that transfer energy between a rotor and a fluid, involves the testing of multiple physical prototypes, which is expensive and takes more time than DOE’s demonstration schedule permits. Ramgen modified this conventional development process by using more extensive computer simulation validated by test results. DOE leadership determined that applying the most capable, high-performance computing systems and modern computational fluid dynamics (CFD) analysis would further accelerate optimizing the turbomachinery’s performance.

Enter Jaguar, one of DOE’s flagship supercomputers located at Oak Ridge National Laboratory’s Leadership Computing Facility (OLCF). With a peak speed of 3.3 petaflops, Jaguar is currently one of the fastest computers in the world. Ramgen was granted time on Jaguar through DOE’s Advanced Scientific Computing Research Leadership Computing Challenge allocation program (https://science.energy.gov/ascr/facilities/alcc/). As a result, the company has been making dramatic progress in designing its advanced turbomachinery for compressing CO2 and also for generating electricity with a breakthrough engine capable of using dilute methane for fuel.

Ramgen has made enormous leaps in its ability to apply the formidable capability of Jaguar to solve complex engineering problems. The accelerated R&D effort is a major factor in the significant reduction in the projected time required to optimize the technology performance for commercial applications; in fact, simulations at the OLCF are guiding testing of prototypes in 2012. These results are an excellent example of what can be accomplished by combining high-performance computing with industry’s R&D.

Why Shock Waves?

Shock waves are a simple and powerful way to compress a gas. Since the sound barrier was broken in the late 1940s, ramjet engines have used shock waves as a means to propel aerospace vehicles at supersonic speeds. The technology is well understood and depends upon shock-wave compression by “ramming” inlet gas into and around a fixed obstructing body in the inlet duct.

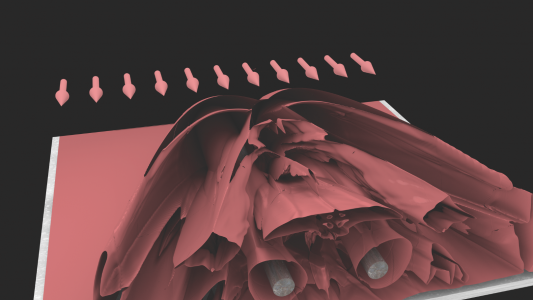

Ramgen is working to apply these shock-wave compression design approaches to a stationary machine to achieve very high levels of turbomachinery performance. This approach offers significant advantages in higher efficiencies and lower costs, but it also requires breaking new ground in modeling fluid dynamics (the study of fluids like air or CO2 and the forces on them) at supersonic speeds. Ramgen’s CFD lead and principal investigator, Allan Grosvenor, notes, “The fluid dynamics involved are incredibly complicated, and limited prior research exists in this specific application. Moving ahead at an expedited rate for such a challenging design necessitates a very powerful computing capability.”

Power of Jaguar Advances Technology

With the expertise and computing power of the OLCF, Ramgen has been able to speed up development of its breakthrough technology through a much more rapid assessment of different design modifications and operating conditions. Only a machine with Jaguar’s computing power is capable of accurately simulating the complex fluid dynamics involved in shock-wave compression technology. Scaling up applications to more effectively use Jaguar’s power is a core capability of the OLCF’s computational scientists.

The OLCF aided Numeca, Ramgen’s software vendor, by providing consultation and direction in improving the performance of Ramgen’s code. Diagnostic tools like Vampir, designed and managed by Technische Universität Dresden, which measures the parallel performance of certain codes running at large scales, allowed for the identification of code bottlenecks, while the adoption of Oak Ridge National Laboratory’s Adaptable I/O System (known as ADIOS) for high-performance file reading and writing reduced problems with initialization and restarts, which improved Ramgen’s use of Jaguar.

These steps resulted in a 100-fold speedup in time to solution and a 2-fold decrease in memory usage per core, which allows higher-resolution computational meshes to be used. Additionally, OLCF’s recent upgrade of Jaguar to the Cray XK6 architecture doubled available memory per core, further improving memory use and enabling greater levels of performance.

Using Jaguar Ramgen has employed sophisticated optimization algorithms, known as “design-of-experiments” techniques, to achieve aerodynamic performance improvement for its shock-wave compression technology. The firm ran hundreds of design combinations with up to 50 design parameters simultaneously (“ensembles”) to find the optimal design solution for the technology. Such a process requires a system like Jaguar with hundreds of thousands of processors, along with sophisticated mathematical algorithms to analyze and predict this optimal solution. Other firms have tried similar experiments but have not been successful. “The use of Jaguar has cut the projected time from concept to a commercial product by at least 2 years and the cost by over $2 million,” said Ramgen’s chief executive officer and director, Doug Jewett.

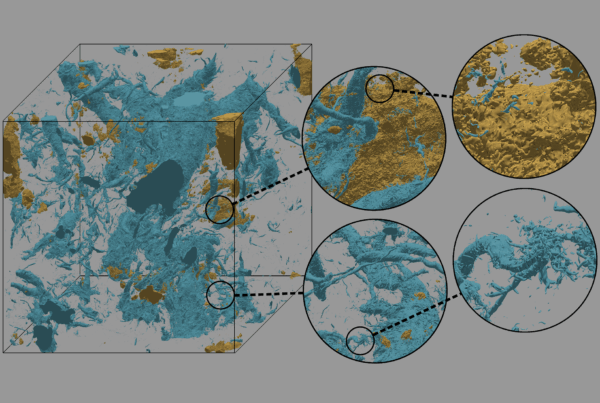

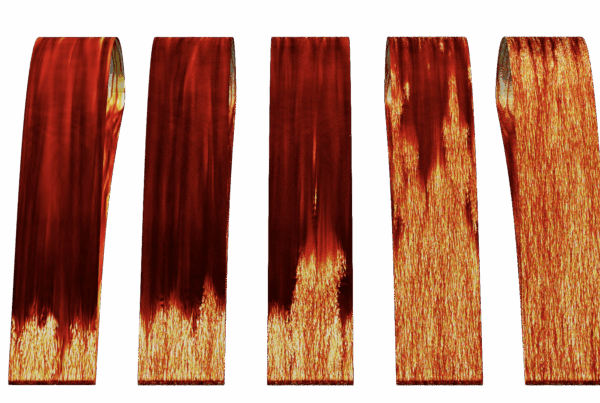

Visualization of mach 3.75 isosurfaces in two body simulation showing complex fluid structures. Image courtesy Michael Matheson, ORNL, and Ramgen Power Systems.

Ramgen’s design ensembles effectively used 80 percent of Jaguar’s available computing resources. This intelligently driven optimization process reduced what used to be months of work to a mere 8 hours. More recently Ramgen succeeded in running ensembles of 240,000 cores that again effectively used 80 percent of the available XK6 system. Ramgen’s Grosvenor noted, “Two years ago it was impossible for us to run an ensemble of simulations like this. The sophisticated design analyses that we are running now are having a significant impact on our turbomachine development work.”Jewett added, “Jaguar provides, in a remarkably short time, data that we use to predict optimal designs. It’s enabling us to advance the design of our equipment in a timeframe that simply would not have been possible without Jaguar and the assistance of Mike Matheson [of the OLCF’s Scientific Computing Group] and the OLCF.”

Accelerating this timeline is critical to the nation’s effort to curb the amount of CO2 emitted into the atmosphere. Thanks to this effective industry–lab partnership and Jaguar’s scalable architecture, Ramgen will initiate testing of a 13,000-horsepower CO2 compressor this year. This compressor is projected to reduce the capital costs of CO2 compression by 50 percent and produce a minimum of 25 percent savings in operating costs. Applying these cost savings to a new 400-megawatt clean coal plant would result in capital cost savings of approximately $22 million and an annual operating cost savings of approximately $5 million.

Capturing More Than Carbon?

Applying the power of Jaguar to shock-wave-based compressors at the scale now being achieved represents a paradigm shift in how new turbomachinery is developed. “I believe that by applying the optimization enabled by Jaguar, Ramgen will accomplish levels of aerodynamic refinement with shock-wave-based technology in 5 years that took 50 years with gas turbines,” said Ramgen’s chief technology officer, Shawn Lawlor.

There is enormous synergy in the work done on shock-wave-based compression for CO2 and the Integrated Supersonic Component Engine (ISC Engine), another product that Ramgen is developing. The ISC Engine will generate electricity—efficiently and cost effectively—using dilute methane gases released during coal mining operations and from landfills. Methane, per volume, traps 21 times more heat in the atmosphere than CO2 but has a shorter atmospheric lifetime compared with it. Engineers from Jim Walter Resources, a mining company, and Ramgen staff have developed an approach that can use up to 75 percent of the methane now being emitted into the atmosphere worldwide as fuel to generate electricity. Currently approximately 90 percent of this methane is simply vented to the atmosphere.

This compression process has additional exciting possible applications with other gases and for other products. “What all these technologies have in common,” said Jewett, “is that they’ll boost the gas pressure significantly at lower cost than alternatives.” With the help of Ramgen’s dedicated engineers and the increasing importance and power of supercomputers such as Jaguar, these technologies can enter the marketplace sooner, proving that together industry and high-performance computing can change the world in profound ways. —by Gregory Scott Jones