HPC keeps American aerospace competitive

A visualization generated with Boeing’s computational fluid dynamics simulations on the OLCF’s Jaguar supercomputer. Image courtesy Molejo Hong, The Boeing Company.

For years, academia has looked to simulation to solve some of science’s most complex problems. Recently, industry has taken notice—America’s most powerful machines are now helping its most powerful companies. Take Jaguar and Boeing, for example.

Boeing researchers used Jaguar recently to validate aerodynamics codes for airplane design, saving substantial R&D time that otherwise would be spent calculating solutions. By using Jaguar, the world’s third-fastest computer, to simulate various takeoff and landing scenarios, the team validated and improved several aerodynamics codes, saving the company time and money and possibly influencing the process by which next-generation Boeing aircraft are designed and manufactured.

Led by Boeing’s Moeljo Hong and John Bussoletti, the suite of computational fluid dynamics simulations not only assists in more efficient modeling and possibly design of passenger and military aircraft, but also gives Boeing an advantage that only high-performance computing (HPC) can provide. And by using its 2010 Innovative and Novel Computational Impact on Theory and Experiment (INCITE) allocation on Jaguar to model airplanes more accurately, Boeing hopes to make them safer and increase their fuel efficiency, reducing US dependence on foreign oil and fossil fuels in general.

The team’s project yielded several interesting discoveries. First and foremost, said Bussoletti, researchers had been under the impression that breaking down a large problem, such as air flow over a full aircraft, into many, many small pieces and solving them in parallel would hinder their ability to achieve an accurate result in a timely fashion. In fact, they learned that any hindrance would indeed be very modest, verifying their research approach and the use of distributed–memory HPC in aviation simulation in general.

Besides greatly assisting engineers in their case to procure more simulation resources, the research proved that leading aerodynamics applications can scale to leadership-class systems and provide insights critical to understanding the complex phenomena associated with aircraft aerodynamics.

“With computational modeling, you have a multi-pronged business opportunity,” said Bussoletti. “You can do everything much faster, or you can broaden your use of computational modeling and explore more [variables] and make a better product.” Boeing’s allocation on Jaguar allowed the world’s leading aerospace firm to do both.

Prepare for Takeoff

Boeing’s research was different from most of Jaguar’s allocations in that each simulation used only a small portion (fewer than 10,000) of Jaguar’s more than 200,000 cores. However, each study solved approximately ten different problems. Had each of these problems been solved simultaneously, said Bussoletti, the team could have used more than 50 percent of Jaguar’s two-plus petaflops of computing power.

The team primarily used two computational fluid dynamics codes that solve the same set of equations, said Bussoletti, with one employing a structured and the other a nonstructured mesh. These two approaches represent a tradeoff between more grid cells in the simulation and the accuracy of the solver, a piece of software that employs an algorithm to solve the equations. By using both approaches, the team can decide which methods yield the best results.

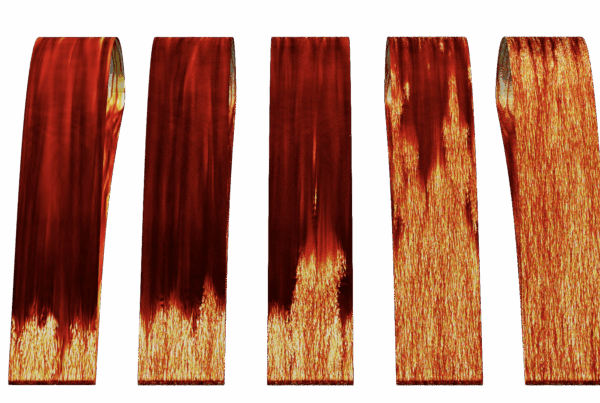

Specifically, the team investigated lift during various takeoff and landing scenarios. They wanted to know the lift and drag at different angles of attack, or the angle between the oncoming air flow and a reference line on the airplane or wing, and how they change with different configurations of the flaps and slats that make up the high lift system.

When it comes to high lift design, there are many constraints that must be balanced against performance requirements. Designers need hundreds or thousands of answers, in this case calculations of various forces against different aircraft components, which help to estimate the distributed load over the entire aircraft structure. This means running thousands of individual simulations, which in turn help to determine the strength of the structure required for safety and the empty weight of the aircraft, among other things.

According to Bussoletti, simulating these systems is computationally intensive, hence the need for Jaguar. And despite the need for one of the world’s largest supercomputers, simulation is much more economical than the traditional investigative tool, experiment, which is costly in both dollars and effort. Whereas the team can model a full-scale aircraft on Jaguar, experimental techniques, such as wind tunnels, require the use of mostly empirical methods to extrapolate airplane characteristics from the scale of the wind tunnel model to the full-scale flight vehicle, which can skew results and possibly create unpleasant surprises in flight tests.

“Jaguar provided us with a unique opportunity to learn that it’s possible to achieve completely converged solutions to steady state computational fluid dynamics equations about high lift aircraft configurations in as little as 2 to 4 hours of wall clock time, saving an order of magnitude over our experiences from use of smaller-scale systems,” said Bussoletti. “Now we’re confidently exploring what impact that can have on our airplane development cycle, both in terms of performance improvements and cycle time reduction.”

The team is handing over its results to Boeing R&D to be analyzed for their value in the design, testing, and manufacturing processes. And while this particular project ran solely on Jaguar, Bussoletti said the success of the simulations has the team looking at furthering its research on Boeing’s in-house systems.

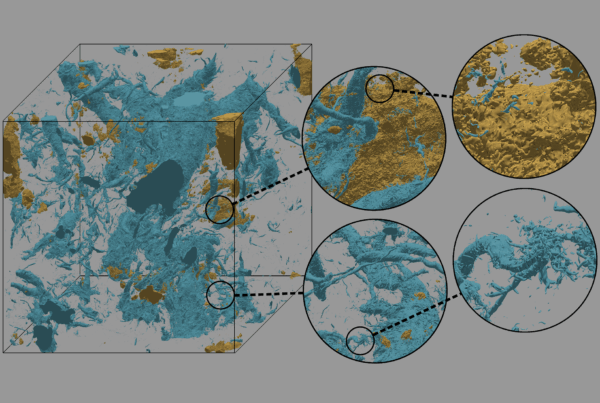

Bussoletti and Hong are now looking to refine their simulations and continue working on adaptive gridding, in which simulations adjust grid resolution to characteristics of the solution without having to know in advance what kind of features exist or where they are.

While most of their earlier research involved fixed grids, (which require the user to “guess” what features are present and provide sufficient resolution to give required accuracy), the adaptive grid simulations will further refine the solution to give researchers a more accurate estimate of aviation aerodynamics, providing Boeing with a valuable tool with which to build the airplanes of tomorrow.

To accurately resolve separated flows (when air flow separates from the fuselage) on a fixed grid would require approximately 1021 nodes, a number so large that the system would have to be more than a thousand trillion times more powerful than Jaguar. With an adaptive mesh, however, that number could be brought down to 107 or 108, an enormous reduction that puts the achievement within reach.

For now, however, Boeing researchers know they are on the right track. HPC has provided an invaluable platform for the study of aerodynamics via simulation, a far more efficient method than experiment in this case. With proven applications, the team can now refine its simulations further and hopefully bring safer, more efficient aircraft to market sooner and cheaper, all the while keeping America competitive in a global economy. — by Gregory Scott Jones