In 2017, the Oak Ridge Leadership Computing Facility celebrated 25 years of leadership in high-performance computing. This article is part of a series summarizing a dozen significant contributions to science enabled by OLCF resources. The full report is available here.

Consumer-products giant Procter & Gamble (P&G), a Fortune 500 firm founded in 1837, came to ORNL in 2011 to better understand microscopic processes that can threaten product performance and stability.

Many of P&G’s products for the body and the laundry are comprised of systems of fat-soluble molecules called lipids. These molecules dictate the flow, thickness, performance, and stability of P&G products.

In 2011, researchers at P&G with colleagues at Temple University turned to ORNL’s Jaguar supercomputer, one of the fastest supercomputers in the world at the time, in an attempt to model and simulate microstructural arrangements of lipid vesicles.

The Science

Understanding lipid additive interactions gives P&G the opportunity to better design products and anticipate stability issues that may affect product performance and consumer satisfaction.

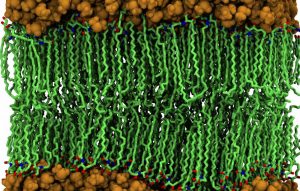

Lipid vesicles form when lipid bilayers “roll” into spheres. Vesicles also can encircle each other like Russian nesting dolls. In the body, vesicles transport insulin, neurotransmitters, and other vital substances in their interiors and then fuse with cell membranes to deliver the contents. In manufactured products such as lotions and fabric softeners, man-made vesicles called liposomes encapsulate and suspend perfumes, dyes, and active ingredients.

Over time vesicles can fuse with each other, causing phases to separate and otherwise threatening consistent product performance. For P&G, it is crucial to understand vesicle fusion in order to extend the shelf lives of such products as fabric softeners, body washes, shampoos, and lotions.

To speed discoveries about why vesicle systems have stability problems, the researchers knew they would need to simulate the reorganization of vesicles over time. Before vesicles fuse, their surfaces strain and break, exposing water-avoiding parts of molecules to an aqueous environment. Following every molecule in a system of fusing vesicles as they contort and combine would be a herculean feat. P&G researchers hoped such simulations would help to predict performance attributes before a product is manufactured, so they would then be able to deliver high-quality products faster than competitors and earn greater revenues in the marketplace. But the magnitude of the challenge exceeded the capabilities of even P&G’s powerful supercomputers. They needed extremely long simulations of extremely big lipid systems made possible by OLCF resources.

With the help of 69 million core hours on Jaguar over two years, they were able to set the stage for simulations of large, complex systems of lipid assemblies. Until then, no one had ever been able to simulate vesicle fusion in realistic systems, such as biological vesicles whose fusion is triggered by proteins. With Jaguar’s computational power, the researchers succeeded in artificially triggering the deformations of a single vesicle that happen before it fuses with another vesicle. The mathematical model applied an electrical field oscillating at 10 megahertz to one vesicle in a simulation that tracked the movements of the 5,000 lipid molecules in that vesicle.

These simulations allowed the team to investigate the very early events associated with the initiation of vesicle fusion. This benchmark simulation allowed comparisons to experimental data that verified the simulation and the interpretation of the experiment.

“These simulations allowed us to investigate the very early events associated with the initiation of vesicle fusion. If you want a complete mechanistic understanding of a process, these details and the capability to study them are extremely important.” —Russell DeVane, Procter & Gamble

The Legacy

P&G has long understood the value of modeling and simulation, applying computational tools to significantly reduce the number of experiments involved in their process design for products like Pampers. The team sought out to achieve a similar goal when designing formulated products like shampoos and fabric enhancers. Since 2011, this team has continued using OLCF resources in developing codes and improving simulations capable of showing how microscopic properties of vesicles influence macroscopic properties, such as phase separation as a product ages. Gaining that type of knowledge has given untold long-term benefit as it helps the company wash its hands of potential poor performers and more quickly embrace formulations that are more likely to grow its fortune.

Related Publication: Fiorin, G.; M. L. Klein; R. DeVane; and W. Shinoda. “Computer Simulation of Selfassembling Macromolecules.” In Hierarchical Macromolecular Structures: 60 Years after the Staudinger Nobel Prize I, 93 -107. Springer International Publishing, 2013.