In 2017, the Oak Ridge Leadership Computing Facility celebrated 25 years of leadership in high-performance computing. This article is part of a series summarizing a dozen significant contributions to science enabled by OLCF resources. The full report is available here.

Since 2007, a team led by ORNL’s Jeremy Smith has used OLCF systems to provide molecular-level insights to help biofuel researchers overcome hurdles to producing cost-competitive cellulosic ethanol fuel and other high-value products from woody plants and waste biomass.

Advanced biofuels hold the promise of reducing US greenhouse gas emissions and fossil fuel dependence with a sustainable energy source that doesn’t compete with food production and contributes to rural development. Realizing this potential, however, requires more efficient processes for converting plant matter into fuel.

Through a series of simulations—ranging from thousands of atoms to more than 20 million—Smith’s team captured key interactions among major components of the plant cell wall, along with the enzymes and solvents used in biofuel production. These results, obtained using the Cray XT5 Jaguar and Cray XK7 Titan, help explain and point toward strategies to mitigate a tenacious obstacle to ethanol production: lignin, a ubiquitous structural component of plants thatblocks the enzymatic breakdown of biomass.

The Science

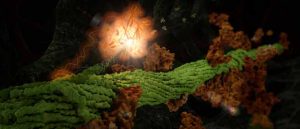

A team at ORNL performed its largest biological simulation to explain why lignin is so potent in blocking the enzymes that break down cellulose. Here, an enzyme (orange) hydrolyzes cellulose (green) despite the presence of lignin (brown).

In nature, lignin helps provide the scaffolding for plant cells, reinforcing the cell wall’s slender cellulosic fibers—the primary raw ingredient of cellulosic ethanol—and serving as a protective barrier against disease and predators. This hardy polymer, however, also makes plants stubbornly resistant to breakdown, or hydrolysis. Therefore, to hydrolyse biomass and make it available for fermentation by microbes, it must first be subjected to large amounts of acid, water, and heat, adding cost and complexity to the process.

Understanding the structure of lignin is critical to devising rational strategies to overcome its adverse effects. So to better understand the lignin problem, Smith’s team first resolved the structure of lignin down to 1 angstrom (equal to 10 billionths of a meter, or smaller than the width of a carbon atom) with the help of Jaguar in 2011. The project revealed the rough and folded surface of the polymer in unprecedented detail.

The team transitioned its research to Titan, on which its atomistic simulations expanded into a representative model of pretreated biomass made up of lignin, cellulose, and enzymes. The simulations in 2014 demonstrated exactly how lignin binds to cellulose and enzymes to block hydrolysis. Furthermore, the team identified a pathway to circumvent the problem, finding that amorphous, or less-ordered, cellulose fibers interact less with lignin and therefore are more accessible to enzymes.

In addition to simulating conventional biomass, Smith’s team used supercomputing resources to provide context to biofuel experiments funded by DOE’s BioEnergy Science Center. In support of one such experiment, the team simulated a promising genetic modification to the lignin of an aspen tree and thus explained why it worked. In another instance, the team subjected an experimental solvent to the OLCF’s “computational microscope” to explain why pretreatment with the solvent was more than three times as effective as conventional dilute acid when applied to maple wood. Both cases highlighted strategies for removing lignin with increased efficiency.

“This detailed knowledge of lignin behavior can guide genetic engineering of enzymes that bind less to lignin and therefore produce bioethanol more efficiently.” —Loukas Petridis, Oak Ridge National Laboratory

The Legacy

As the first group to perform supercomputer simulations on biomass, Smith’s team demonstrated the value of identifying molecular mechanisms to explain problems in multicomponent molecular systems. Leveraging these insights, biofuel researchers have accelerated progress toward the production of economically viable cellulosic ethanol, a vision that predates the world’s first mass-produced automobile.

The team’s work also spearheaded a shift in computational biophysics from individual molecules and proteins toward more complex, multicomponent systems. This transition was largely enabled by petascale resources, beginning with the OLCF’s Jaguar, that continue to grow, allowing for the simulation of biomolecular systems of even greater size and complexity.

Related Publication: Mostofian, B., et al. (2016), “Local Phase Separation of Co-solvents Enhances Pretreatment of Biomass for Bioenergy Applications.” Journal of the American Chemical Society, Volume: 138, no. 34. DOI: 10869–10878.