Bart Hammontree began working as a subcontractor at ORNL in 1992. Now serving in a full-time position as a member of the UT-Battelle Development Corporation, Hammontree has overseen construction and retrofit projects both small and large in scope.

The Faces of Summit series shares stories of the people behind America’s top supercomputer for open science, the Oak Ridge Leadership Computing Facility’s Summit. The IBM AC922 machine launched in June 2018.

When the Oak Ridge Leadership Computing Facility’s (OLCF’s) next leadership-class supercomputer, Summit, goes live in 2018, visitors to the computer room will experience the sights and sounds associated with such powerful machines.

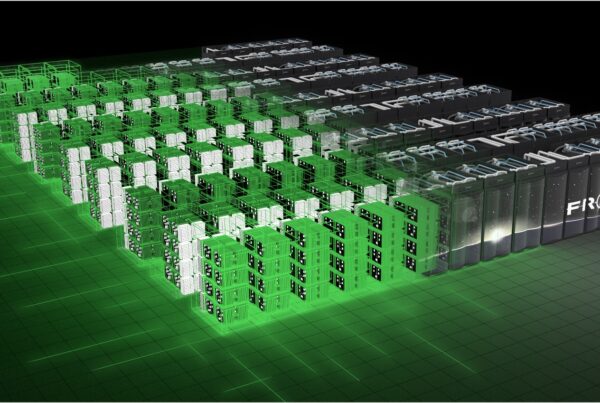

The tops of tall, dark cabinets will loom overhead, lights will blink in various sequences and colors, and the audible buzz of technology will fill the space. Visitors will see the end product of years of planning, development, and construction. Bart Hammontree, however, will still remember the massive engineering project that began in a large, empty room.

Hammontree serves as the project manager for facility upgrades at the OLCF, a US Department of Energy (DOE) Office of Science User Facility located at DOE’s Oak Ridge National Laboratory (ORNL). He is currently managing construction of the Summit computer room and infrastructure. In the simplest of terms, Hammontree has been responsible for preparing the physical space where Summit will reside—but in the worlds of construction and supercomputing alike, few things are ever simple.

Hammontree and his team were responsible for the design and construction of the mechanical room that supports Summit. Chilled water pipes support heat exchangers responsible for maintaining optimum water temperatures for the supercomputer.

“Much of the focus of my work in the last 10 years has been on making modifications to existing buildings at the lab to prepare them for these large installations,” Hammontree said. “The three largest components my team and I look at are the power, space, and cooling required for these systems. For Summit specifically, this meant preparations such as converting what used to be office and lab spaces into mechanical rooms to bring cooling water to the machine.”

Long before anything resembling a supercomputer structure was rolled into the Summit room, Hammontree’s team poured its expertise and energy into providing Summit with its most basic needs—space for cabinets, electricity for power, and water for cooling. Although their efforts often may be hidden behind walls, within schematics, and inside mechanical rooms, engineering and construction employees’ contributions have provided a strong canvas on which to sketch future generations of supercomputers.

Staying flexible

Cooling is the most difficult part in planning and maintaining a supercomputing system. OLCF systems such as the Cray XK7 Titan have relied on a cooling system that chills and delivers 42‑degree-Fahrenheit water to the system. At the same time, a secondary loop carries water away from the supercomputer to the chilled primary loop. Though this cooling method has sustained the life of powerful resources such as Titan, the process is expensive, composing about 23 percent of Titan’s $7.8 million annual operating budget.

Whereas Summit shares with Titan a need for water cooling, Hammontree’s team innovated a way to cool Summit—and future supercomputer installations—more efficiently. The mechanical room Hammontree’s team designed will house a water-delivery system that provides cooling in name only. Instead of pumping water that’s frigid to the touch, the mechanical room forgoes expensive chillers and instead acts as a conduit for water of about 70 degrees Fahrenheit—nearly 30 degrees warmer than what Titan requires. For Tennessee’s hottest of summer days, the 42‑degree system will serve as a backup to cool Summit.

Water used to cool Summit originates from a municipal source, undergoes treatment, and is kept at approximately 70 degrees Fahrenheit, a much more energy efficient temperature to maintain in comparison to Titan.

The work that went into making Summit’s water delivery systems more efficient is one of Hammontree’s proudest accomplishments.

“As a mechanical engineer by degree, I thought coming up with innovative ways to cool the machine was the most interesting challenge. We came up with this idea of taking what would have been two large loops of water of different temperatures and combining them. It was a huge money saver and provided us with a lot more physical space to work with,” Hammontree said. “In terms of providing the water cooling that we need, we have yet to find a problem that we couldn’t solve.”

Though commonalities in basic utility and space needs exist between Summit and Titan, the differences between the two machines and the rooms they reside in will be immediately visible to the naked eye. Instead of the raised floor that houses Titan’s cables and wires, Summit’s one-of-a-kind space will allow for cooling and power infrastructure to pass overhead of the computer cabinets rather than beneath them.

“I think that is one of the really interesting differences about the space that Summit is in compared with Titan. With the infrastructure passing along the ceiling unobstructed, you get a real appreciation for the complexity and power of this system,” Hammontree said.

Career construction

Hammontree began his career at ORNL in 1992 with a job much smaller in scope than his current projects. During the past 25 years, he has had ample time to develop an appreciation for campus construction.

“Right after I finished my degree in mechanical engineering at the University of Tennessee, Knoxville, I started working here as a subcontractor,” Hammontree said. “My very first project here was pouring a concrete slab to house some nitrogen tanks.”

After a decade of developing his project management expertise, Hammontree accepted a full-time position as a member of the UT–Battelle Development Corporation. Hammontree and members of his team have left their literal and figurative fingerprints on new construction projects and on the modification of existing ORNL campus structures.

With projects as vast as building a leadership-class supercomputer, the stakes are high and the work is complex. However, Hammontree—a self-described professional problem-solver—finds many rewards, even after long days adapting to new challenges.

“Every week I hear about a new accomplishment that has been achieved through Titan,” Hammontree said. “Then I go home and I tell my wife, ‘This is why I’m doing this.’ Those accomplishments are only going to get bigger with Summit.”

The Faces of Summit series shares stories of people working to stand up America’s next top supercomputer for open science, the Oak Ridge Leadership Computing Facility’s Summit. The next-generation machine is scheduled to come online in 2018.

Oak Ridge National Laboratory is supported by the U.S. Department of Energy’s Office of Science. The single largest supporter of basic research in the physical sciences in the United States, the Office of Science is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.