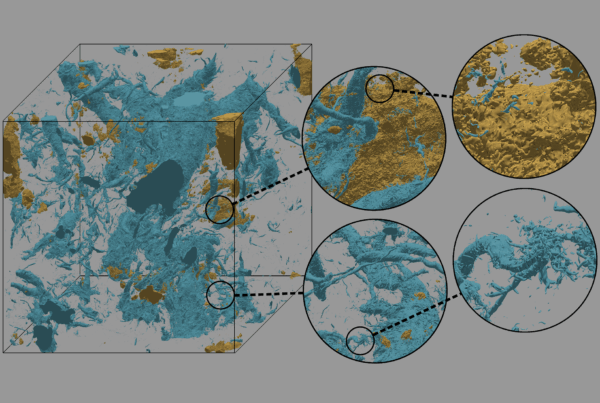

A recent cover of the journal Nanoscale depicts simulation of liquid-crystal “mesogens,” represented by blue units, which make up a thin film placed on a substrate, whose units are shown in white. Over time the thin film forms large holes as mesogens redistribute to regions of lower energy—a process called dewetting—until the film ruptures. Image credit: Michael A. Matheson. Image courtesy of Royal Society of Chemistry.

Oak Ridge National Laboratory computer aids large-scale exploration of rupture mechanism

Thin films engineered from high-tech materials need to be slender (to control costs) but stable (to ensure effectiveness). Among their valuable uses are protecting pills from early disintegration, metals from corrosion, and hard drives from friction. But make thin films out of liquid crystals—a diverse family of macromolecules composed of rigid and flexible segments—and their powers expand.

Because their rigid segments can align in response to electric current, magnetic field, light, temperature, and other factors, liquid-crystal molecules are the mojo behind today’s flat-panel electronic displays and may provide the might behind tomorrow’s nanoscale coatings, optical and photovoltaic devices, biosensors, and more.

But liquid-crystal thin films can rupture, or tear apart. A thin film that has been spread on a substrate tends to develop holes, or “dewet.” During this process matter diminishes on thin parts of the film, which are under great strain, but builds up on other parts of the film, thickening them. Despite the appearance of larger and larger holes in the film, the overall volume of matter stays the same. To gain better control over liquid-crystal thin films, researchers want to improve their understanding of the driving force for that process.

Approximately four decades ago, theoreticians believed that only one of two mechanisms could explain dewetting. They also believed that these two mechanisms could not coexist.

“The problem is that about 10 years ago experiments showed that these two mechanisms in many cases do coexist,” said postdoctoral fellow Trung Nguyen of Oak Ridge National Laboratory (ORNL), who ran unprecedented large-scale molecular dynamics simulations on Titan, America’s fastest supercomputer, to model the beginnings of ruptures in thin films wetting a solid substrate. The work appeared as the cover story in the March 21, 2014, print edition of Nanoscale, a high-impact journal of the Royal Society of Chemistry, and was also published online.

“This study examined a somewhat controversial argument about the mechanism of the dewetting in the thin films,” continued Nguyen, who was coprincipal investigator on the project with W. Michael Brown (formerly of ORNL, but now of Intel). Their coauthors, both at ORNL, were postdoctoral fellow Jan-Michael Carrillo, who helped develop the simulation model, and computational scientist Michael Matheson, who developed the software necessary for visualization and analysis of huge systems of liquid crystals.

The first proposed mechanism, thermal nucleation, posits that the heat-related movement of atoms in the film randomly initiates holes. The second, spinodal dewetting, asserts that small undulations on the thin film’s surface grow in amplitude over time until they touch the substrate, causing the formation of holes that expose it. Theoretical models of hydrodynamics predict that a dewetting thin film should take one pathway or the other, depending on its initial thickness.

Nonetheless, experimentalists observed features of both mechanisms simultaneously in polymeric films. “That’s the controversy that the conventional theoretical model had to resolve,” Nguyen said.

The ORNL researchers proposed a hypothesis to reach such a resolution and brought it to life with a simulation that validated the experimental results. It turned out the mechanisms indeed coexist, but one will be more discernable than the other depending on the initial thickness of the film. Spinodal dewetting characteristics are most pronounced in very thin films. “But if you make the film thicker and thicker, thermal nucleation features become dominant,” Nguyen said.

The researchers found that the driving force for rupture is related to liquid-crystal molecules striving to recover lower-energy states. This finding, which may improve understanding of the thin films used in energy production, biochemical detection, and mechanical lubrication, was made possible through a 2013 Titan Early Science program allocation of supercomputing time at the Oak Ridge Leadership Computing Facility. Nguyen’s team gained entry to Titan through ORNL’s Center for Accelerated Applications Readiness (CAAR), which gives early access to leadership computing resources to users with scientific application codes capable of employing graphics processing units (GPUs) at scale. The allocations promote a vanguard set of codes capable of exploiting Titan and scientific problems requiring that much computational power.

Through CAAR Brown developed the LAMMPS molecular dynamics code to run in accelerated mode using GPUs, and Nguyen and Brown’s science problem was deemed a high priority.

Simulating rupture

In reality liquid-crystal molecules exist in melts, or float in aqueous solutions. In computer models they are often represented as oval-pill-shaped units. These ellipsoid “mesogens” summarize the characteristics of the molecules’ rigid and flexible segments. That simplification means the researchers do not have to explicitly simulate the bonds between atoms in the molecules—an approach that allows simulation at much longer timescales. “In our model we incorporate the nonspherical shape of the rigid segment and the total effects of the solutions and flexible segments into the interaction between two ellipsoids,” Nguyen explained.

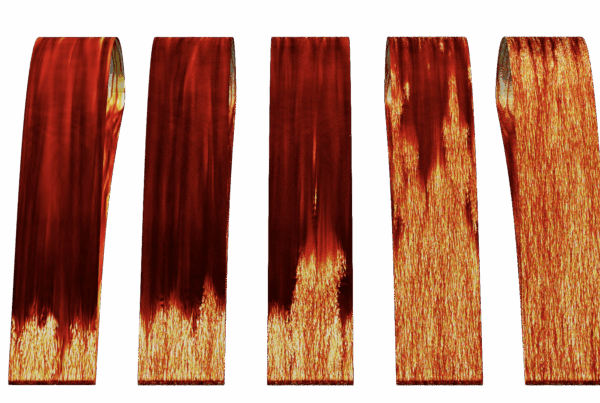

The scientists simulated up to 26 million mesogens on a substrate micrometers in length and width. The study took 18 million core hours and used up to 4,900 nodes of the Titan Cray XK7, a hybrid-architecture system with both GPUs and central processing units (CPUs). It explored the movement over microseconds of mesogens in two different liquid-crystal phases. In the isotropic phase, mesogens have random alignment; they point in all directions. In the nematic phase, however, mesogens have some orientational order, meaning they loosely organize along a certain direction.

The team’s study took around 3 months but would have taken approximately 2 years without Titan’s GPUs. “We’re using LAMMPS with GPU acceleration so that the speedup will be seven times relative to a comparable CPU-only architecture—for example, the Cray XE6. If someone wants to rerun the simulations without a GPU, they have to be seven times slower,” Nguyen explained. “The dewetting problems are excellent candidates to use Titan for because we need to use big systems to capture the complexity of the dewetting origin of liquid-crystal thin films, both microscopically and macroscopically.”

The team’s simulation is the first to study liquid-crystal thin films at experimental length- and timescales. “No one has ever simulated such big films for such a long time,” Nguyen said. “Another first is to relate all the dewetting process to the molecular-level driving force.”

The researchers’ simulation reproduced dewetting patterns that were in remarkable agreement to images captured during experiments, according to Nguyen.

“Liquid-crystal molecules in a thin film want to recover the conditions they would have in the bulk state, where they have lower energy and more entropy [freedom],” Nguyen explained. “That’s the driving force for thin films to break up and dewet.”

The thicker the film, the more the liquid-crystal molecules feel like they’re in the bulk. So it takes more time for thicker films to rupture.

“This perspective on film rupture can help in the rational design of films with desirable properties due to the wealth of data available for molecules in the bulk phase,” continued Nguyen.

‘Smart’ materials

Simulations could aid scientists in exploring the exposure of liquid-crystal thin films to heat gradients, electric fields, magnetic fields, or light. The knowledge gained may have commercial promise.

Consider that optical or mechanical properties of liquid crystals may differ if the crystals are aligned parallel to a substrate rather than perpendicular to it. In future “smart” insulators, liquid-crystal thin films could exploit these differences. Suggested Nguyen, “If we align the mesogens one way, the heat conductivity is so low that you can insulate the heat from the inside or the outside. But if you rotate the mesogens 90 degrees, heat conductivity along that perpendicular direction may be higher.”

RELATED PUBLICATION

T. D. Nguyen, J.-M. Y. Carrillo, M. A. Matheson, and W. M. Brown, “Rupture mechanism of liquid crystal thin films realized by large-scale molecular simulations,” Nanoscale 6 (2014): 3083–3096.