By Caryn Meissner, ECP contributing writer

Outside the high-performance computing, or HPC, community, exascale may seem more like fodder for science fiction than a powerful tool for scientific research. Yet, when seen through the lens of real-world applications, exascale computing goes from ethereal concept to tangible reality with exceptional benefits.

Imagine a future with an uninterrupted availability of energy resources — providing affordable, reliable power across the country and sustainable energy practices around the globe. Imagine more effective treatments for debilitating, and even deadly, diseases. Imagine innovative aerospace technologies that operate much more efficiently, consume less fuel, and reduce carbon and other emissions. Exascale computing can help accelerate realization of these ambitious goals.

Over the last seven years, the Department of Energy’s Exascale Computing Project has been bringing together multidisciplinary teams of computational experts to advance next-generation computing architectures and revolutionize scientific simulation. One of the hallmarks of ECP has been the collaboration with the industrial supercomputing user community through the project’s Industry and Agency Council, who have helped promote exascale research and development and the successful integration of software technologies, applications and hardware to deliver a fully capable exascale ecosystem. For them, exascale capability opens pathways to explore promising new technologies and products and accelerate time to commercialization.

“Exascale is a massive accelerator for technology, productivity, engineering and science,” said Dave Kepczynski, chief information officer for GE Research and co-chair of ECP’s Industry and Agency Council.

Exascale machines are the most powerful computers in the world. Able to perform a quintillion — or a billion billion — or more operations per second, exascale machines outpace their immediate predecessors, petascale systems, by 1,000 times and are 1 million times faster than DOE’s first terascale computer that debuted in 1996. As a result, exascale computing offers an unprecedented capability for simulating complex scientific phenomena with greater realism and detail than ever before.

“Exascale delivers the speed, scale and fidelity to enable early design and development of new technologies with high levels of confidence in digital engineering and modeling and simulation results,” said Kepczynski.

At GE Research, the innovation engine and central technology development arm for GE, exascale is supporting the company’s motto to “bring research to reality” by driving technology innovation in areas such as healthcare, energy and aerospace. Indeed, exascale is already playing a role in the company’s endeavors to deliver significantly advanced aviation technologies.

Changing the “future of flight”

Aviation is made possible through the application of complex engineering, mechanics, fluid dynamics, physics and materials science. Inside jet engines, gas turbines convert the energy generated from burning fuel into high-temperature, high-pressure rearward airstreams that propel aircraft forward. However, a byproduct of internal combustion processes is the release of carbon dioxide and nitrogen oxides, greenhouse gases that have been linked to climate impacts. For GE Research, exascale computers at DOE are becoming a useful tool for virtually testing new engine designs to achieve greater fuel efficiency and reduce CO2 emissions.

“Developing game-changing new aircraft engines requires game-changing technical capabilities. With supercomputing, GE Aerospace engineers are redefining the future of flight and solving problems that would have previously been impossible,” said Mohamed Ali, vice president and general manager of engineering for GE Aerospace.

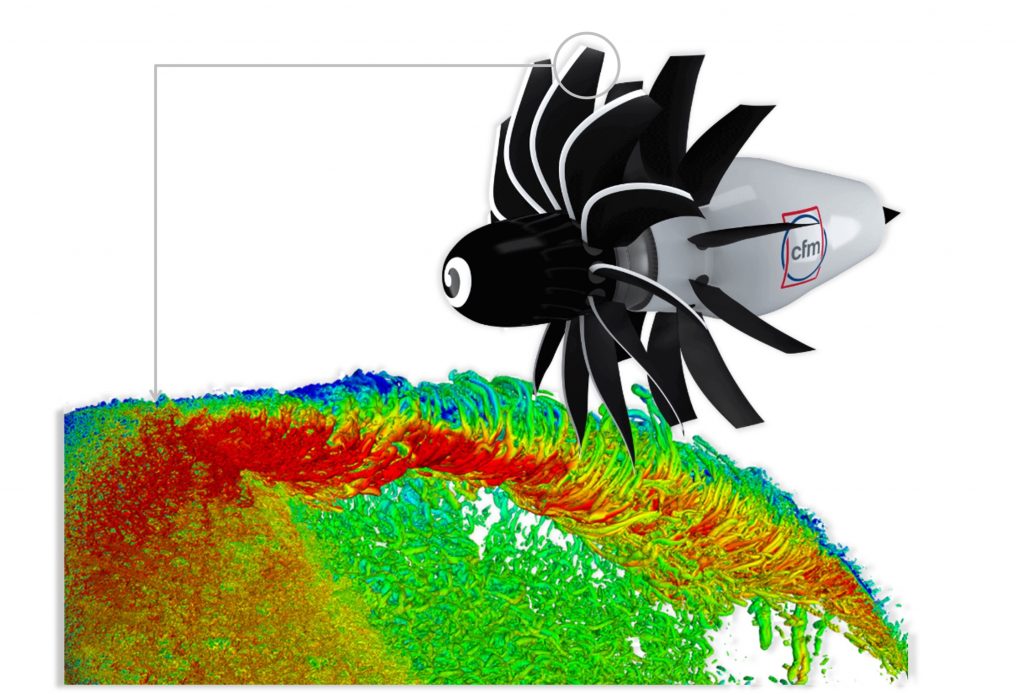

GE Aerospace is partnering with French aerospace company Safran, through the joint venture CFM International, on a next-generation technology demonstration program called Revolutionary Innovation for Sustainable Engines, or RISE, which aims to reduce fuel consumption and CO2 emissions by 20% compared to today’s most efficient engine technologies. The high-fidelity modeling and simulation capabilities provided by exascale computers enable researchers to better discern the underlying physics and scientific principles of jet engine design and performance.

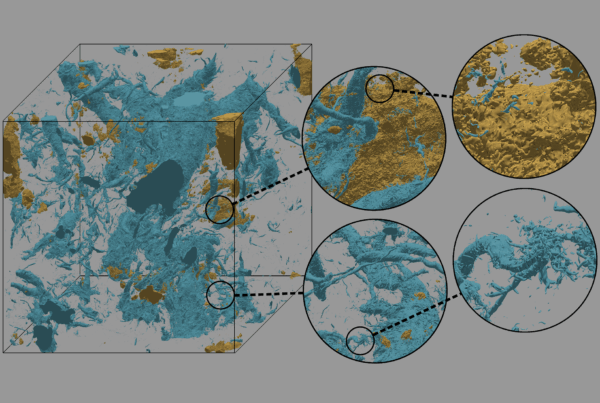

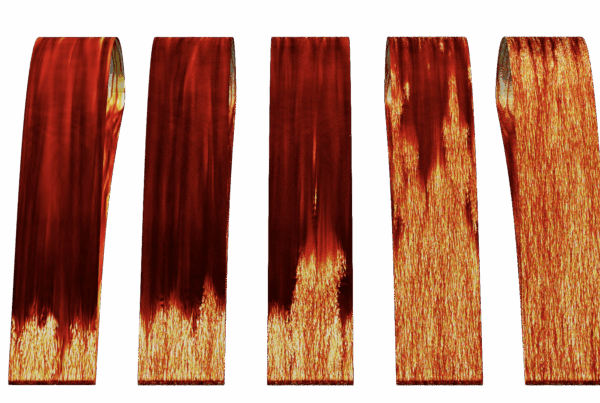

Exascale allows researchers to assess design trade-offs, from the microscopic features of turbulence to the macroscopic effects of how these flow features evolve and affect system performance and noise. Modeling, simulation and analysis help researchers gain insights into the physics of parts and systems to more clearly understand how newly manufactured materials and components will perform under the intense, dynamic conditions of operation.

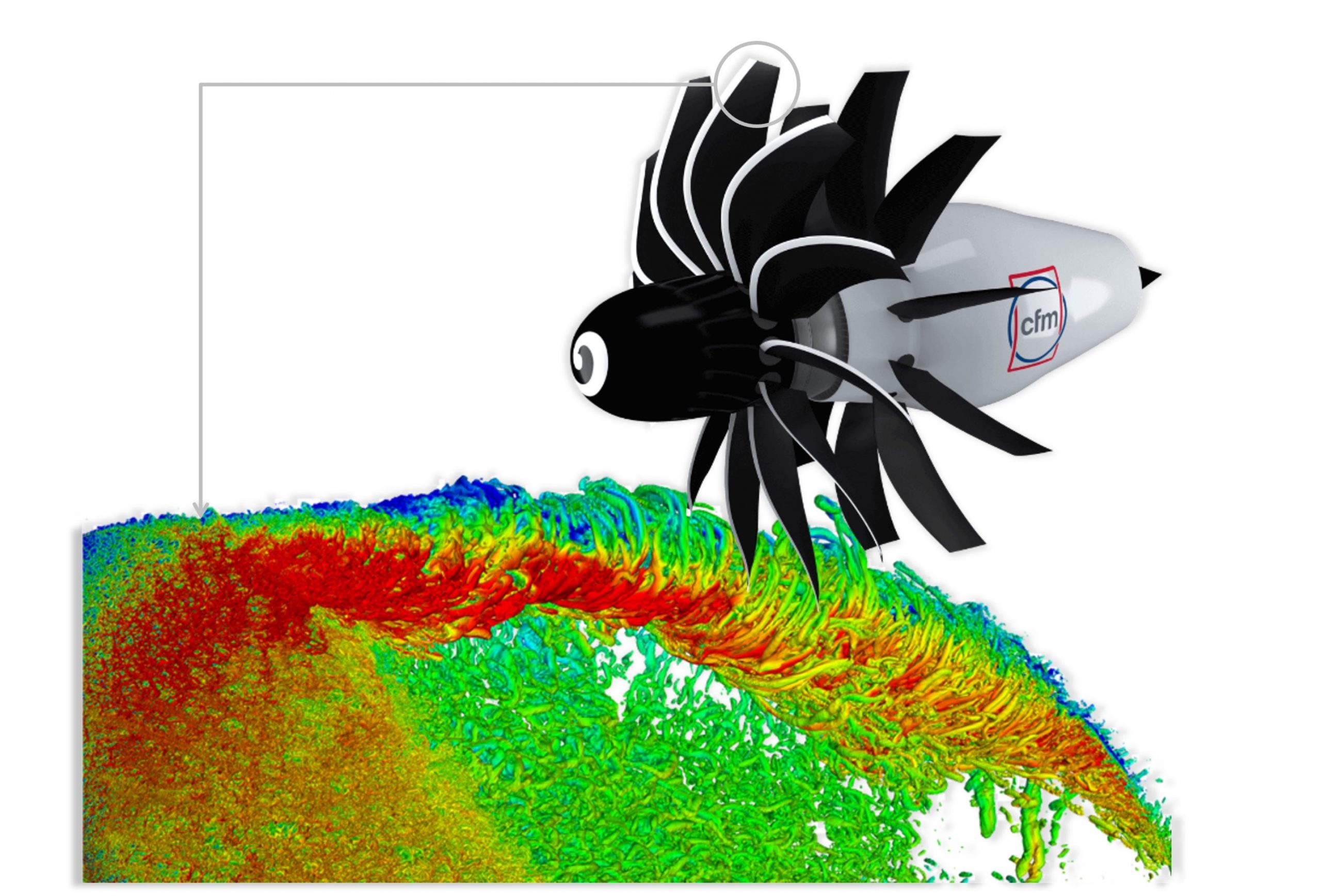

Recognizing the need for exascale-level computing to simulate important aspects of their design, GE Aerospace applied for and was awarded access to DOE’s Frontier supercomputer through the agency’s competitive peer-reviewed Advanced Scientific Computing Research Leadership Computing Challenge. Frontier is an HPE Cray EX supercomputer located at the Oak Ridge Leadership Computing Facility at Oak Ridge National Laboratory in Tennessee and is the world’s fastest supercomputer and first exascale system. Using GE’s custom code for modeling computational fluid dynamics, researchers were able to evaluate aerodynamic and acoustic aspects of the RISE program’s next-generation engine design, an innovative open fan architecture to improve operational efficiency within acceptable noise requirements.

These types of simulations are computationally intensive, requiring significant compute time to resolve the necessary length and timescales. With Frontier, researchers for the first time can simulate the movement of air and complex flow characteristics at full flight-scale conditions and reveal previously unresolvable details of operation.

“To compute such high-fidelity results would have been considered impossibly out of reach even a few years ago,” Rick Arthur, GE Research’s senior principal engineer for Advanced Computational Methods Research, said.

From a development standpoint, these much improved simulations provide computational predictions that more closely match what would be expected from physical experiments. As a result, researchers gain insight into realistic performance from design options years ahead of building the physical system. Research investment can then be spent more wisely on the most promising designs, accelerating time to production and resulting in substantial cost-savings.

The complex scientific problems being investigated with Frontier also lay the foundation for design improvements crucial to advancing jet engine design toward alternative fuels like hydrogen and sustainable aviation fuels as well as new hybrid-electric technologies. The next generation of computing and digital technologies are enabling aircraft fuel volume analysis and optimization, hydrogen fuel storage development and new engine performance efficiencies.

According to GE Aerospace, 650,000 people are flying at any given time on commercial aircraft powered by GE technology. This ubiquity coupled with the fact that last year more than a billion people traveled by aircraft means that developing more efficient, cleaner burning jet engines is not just a goal, it’s a necessity, and exascale is leading the way.

A rendering of the CFM RISE program’s open fan architecture. (bottom) A GE visualization of turbulent flow in the tip region of an open fan blade using the Frontier supercomputer at the Department of Energy’s Oak Ridge National Laboratory. Image Credit: CFM, GE Research (CFM is a 50¬–50 joint company between GE and Safran Aircraft Engines)

Delivering on a promise

Exascale modeling, simulation and data analysis capabilities are just beginning to show their immense value. As can be seen from the work with GE, exascale serves to strengthen the nation’s economic competitiveness and position at the forefront of global technology advancements.

“Over the last five to six years, as a result of the nation’s Exascale Computing Initiative and the significant progress made as part of ECP, we are now delivering on the promise of next-generation computing capabilities that enable these significant advances in technology and breakthrough products that have real implications for the future,” Kepczynski said.

DOE’s exascale development strategy has also helped industry glean valuable insight into developing their own supercomputing capabilities to further research objectives.

The enormous leap in capability from petascale to exascale was made possible through seemingly impossible advances in computing technologies and the collective talent of many people who have been involved with ECI and ECP.

“To see supercomputing reach this level of performance in a relatively short period of time is really astounding,” said Kepczynski.

As a result, exascale computing is now ushering in a new chapter in scientific discovery. Looking to the future, ECP’s capable exascale computing ecosystem has the potential to influence numerous industries. With sustained commitment to this vital capability, many more scientific breakthroughs and advanced technologies are on the horizon. Imagine the possibilities.