by Sara Shoemaker

Mixing metals into alloys is an age-old practice. The tedious trial and error of heating, cooling, testing, and remixing was once the only method to fine-tune the best blend of metals for ideal strength and durability. In recent times, computational scientists have developed a faster, more precise approach.

With sophisticated modeling and powerful, high-performance computing, they have reduced the guesswork by simulating mixed metals down to the single atom. This knowledge could lead to high-quality alloys with superior performance in a wide range of applications.

“The specific position of an atom of one element in relation to the atom of another element can make a huge difference in an alloy’s properties and how it impacts tensile strength and resistance to damage,” said Markus Eisenbach, a computational scientist with the Oak Ridge Leadership Computing Facility (OLCF) who specializes in condensed matter and materials science mostly related to alloys and magnetic systems.

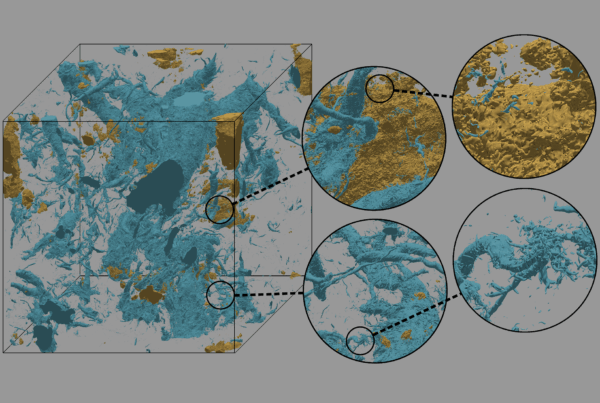

An alloy may comprise only two or three elements. Yet pinpointing each atom’s position and assessing the metal’s magnetic behavior within the underlying crystal structure produces massive amounts of data.

To tackle the enormous task of single-atom calculations, Eisenbach and colleagues at the US Department of Energy’s (DOE’s) Oak Ridge National Laboratory (ORNL) along with other collaborators used the Locally Self-consistent Multiple Scattering, or LSMS, electronic structure code, which originated at ORNL.

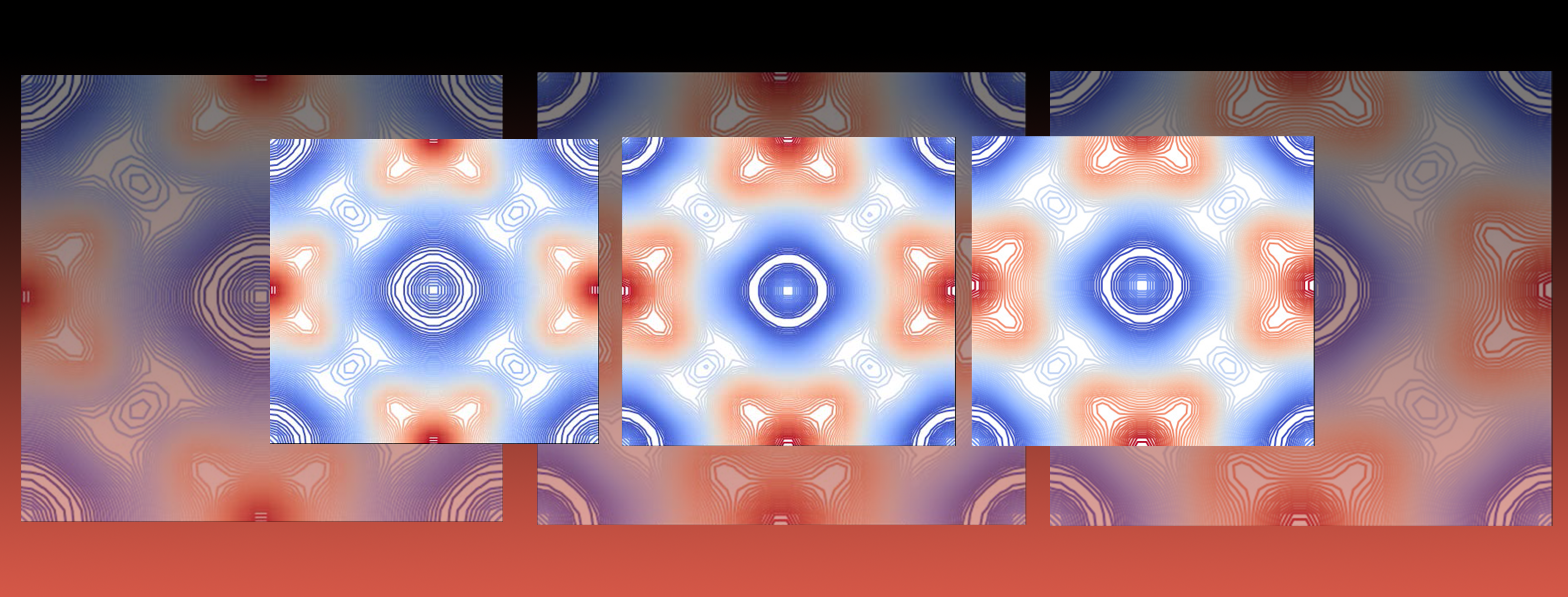

In a paper published in the Journal of Physics: Condensed Matter, Eisenbach led a review of simulations to test first-principles theories related to the phase transitions of what’s known as solid-solution alloys. Many of the calculations described in the paper were run on the Cray XK7 Titan supercomputer at the OLCF, a DOE Office of Science User Facility at ORNL.

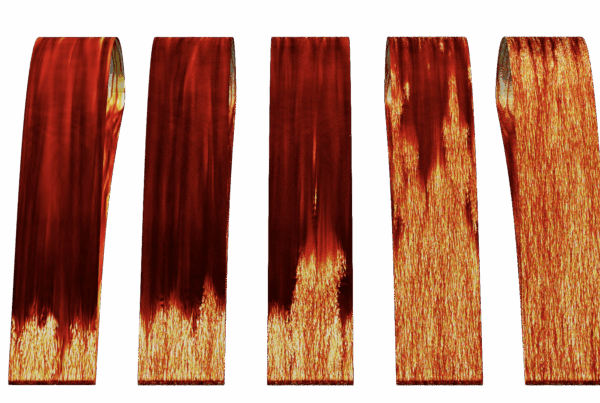

“With this research, we are trying to determine when the atom placement changes from ordered to disordered, meaning at what temperature these phase transitions happen,” Eisenbach said.

When applying first-principles theory, scientists try to make minimal assumptions about the materials being studied, focusing instead on the known elements’ crystal structure and the ordering of the atoms within the structure. They then determine a way to measure the characteristics of the atoms as they shift from ordered to disordered and at what temperature during the simulation.

The LSMS code simulates each atom’s location in a neatly arranged configuration. It also accounts for a change in configuration or phase, similar to when ice melts into water, as the temperature rises or falls.

The code assigns each individual atom in a simulated alloy to a single node of the supercomputer’s parallel architecture. During the calculations, each node detects the possible impact an atom of one element has on a neighboring atom, whether it’s from the same element or a different one, among the mix of metals.

The unique capability of LSMS, which has been further developed by the lab’s Materials Theory Group, can find the temperature change in materials and calculate phase transitions that lead to the difficult-to-predict disordered patterns in an alloy.

Technologically, it is important to understand whether the materials are ordered or disordered, because that can greatly impact their properties, such as whether they can be more ductile or brittle, Eisenbach said.

Based on the theories included in this review study, the scientists showed that the calculation of the ordering of the atoms in an alloy provides a better understanding of their performance.

“This requires quite a lot of computing power—hundreds of thousands of calculations of many different configurations of energies—which wouldn’t have been possible before Titan,” he added.

More metals, more computing power

Eisenbach and colleagues continue their first-principles studies into alloys and magnetic materials on an ever larger scale. And that requires the expanded computing power of the IBM AC922 Summit, OLCF’s 200-petaflop supercomputer that succeeded Titan, which was decommissioned in August.

“We are looking now at Summit to continue this work, running calculations on more complicated materials that make up certain alloys, and incorporating artificial intelligence techniques to improve the performance of the statistical mechanics simulations,” he said.

Eisenbach said they hope to push the boundaries even further as they plan to run calculations on Frontier, ORNL’s first exascale system expected to arrive in 2021; Frontier will have the capacity to analyze potential defects in a microstructure of complex, multicomponent materials.

Related publication: Markus Eisenbach, Zongrui Pei, and Xianglin Liu, “First-Principles Study of Order-Disorder Transitions in Multicomponent Solid-Solution Alloys.” Journal of Physics: Condensed Matter 31 (2019), 273002, doi:10.1088/1361-648X/ab13d8.

UT-Battelle LLC manages Oak Ridge National Laboratory for DOE’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. DOE’s Office of Science is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science.