Frontier is an exascale computer planned for delivery at the Oak Ridge Leadership Computing Facility in 2021. The system will support a wide range of scientific applications for advanced modeling and simulation, as well as high-performance data analytics and artificial intelligence. In the “Science at Exascale” Q&A series, researchers working on these next-generation scientific applications discuss what they hope to achieve on Frontier.

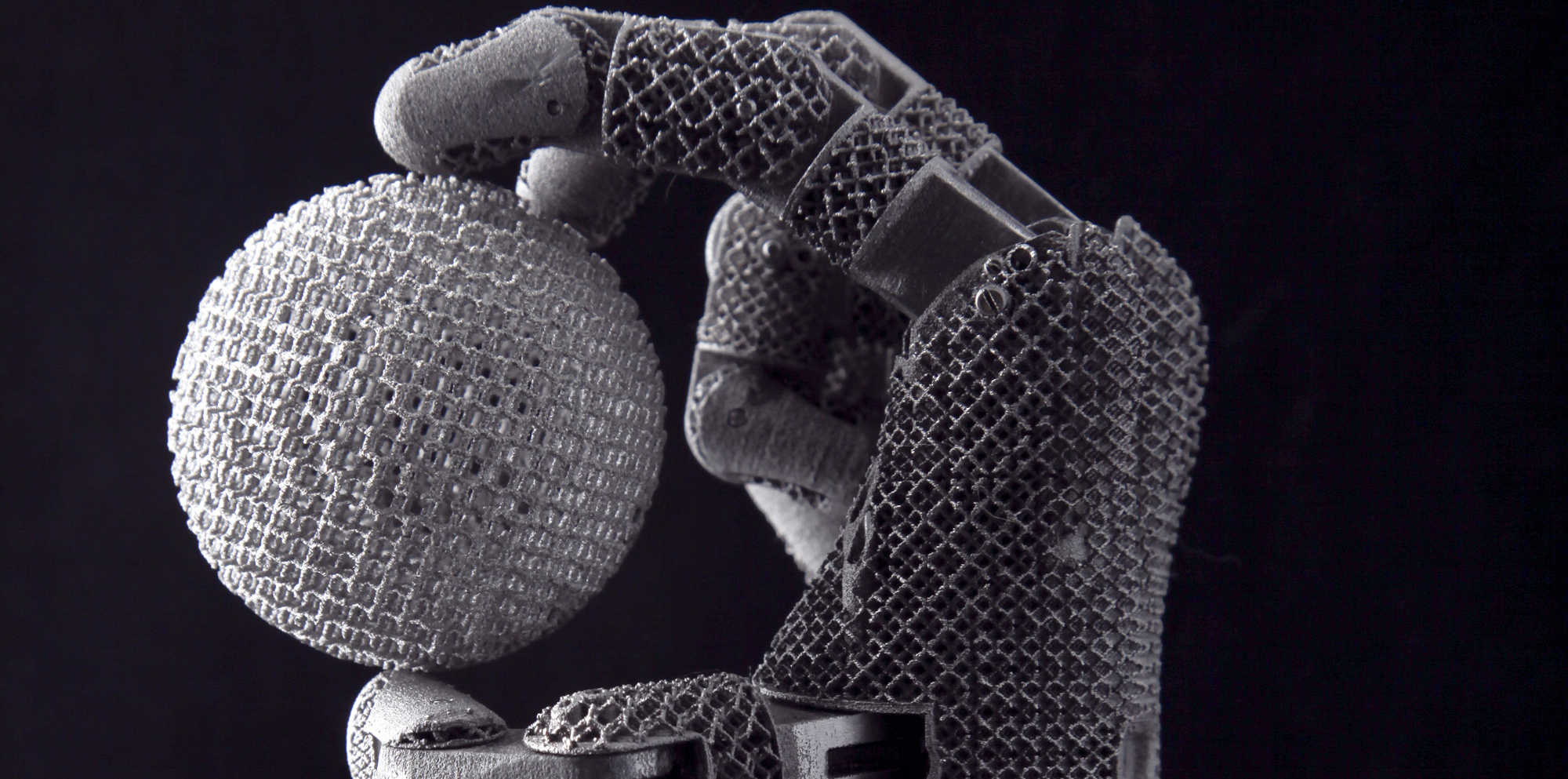

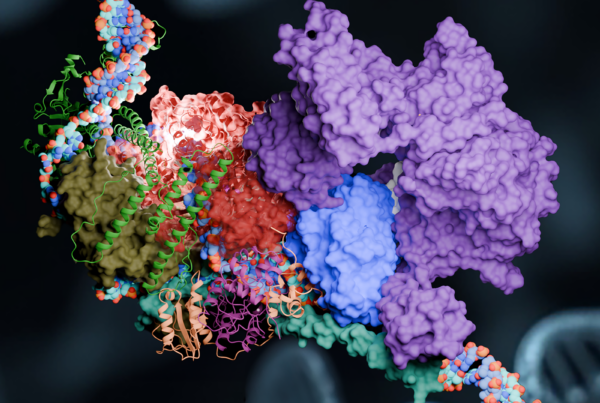

Additive manufacturing, the process of creating objects from 3D model data, is revolutionizing manufacturing by allowing for the construction of parts not readily fabricated by traditional techniques. The Exascale Additive Manufacturing (ExaAM) project is developing a suite of advanced simulation capabilities that will enable scientists to gain a better understanding of the complex relationship between process parameters (such as scan pattern), material microstructure (distribution of grain sizes and orientations), and the resulting properties (such as strength) of 3D-printed metal parts.

Location-specific information about the microstructure and properties of 3D parts will allow scientists to predict the performance, strength, and lifetime of a part; accelerate the qualification and certification of parts; and lead to cost reductions and energy savings as well as new and improved products. Scientists must currently make numerous approximations and simplifications when predicting the microstructure of additively manufactured parts. With Frontier, the exascale system scheduled to be delivered to the US Department of Energy‘s Oak Ridge National Laboratory in 2021, scientists will be able to remove a number of these approximations and optimize parameters used in the manufacturing process, enabling the design of lighter parts with less waste, fewer components to be assembled, or other attributes depending on the application.

In this interview with John Turner, principal investigator for ExaAM in the Exascale Computing Project, he describes how exascale computing with systems like Frontier will allow his team to study materials in greater detail than ever before.

In this interview with John Turner, principal investigator for ExaAM in the Exascale Computing Project, he describes how exascale computing with systems like Frontier will allow his team to study materials in greater detail than ever before.

What is the science problem you’re working on?

Turner: Our project, Exascale for Additive Manufacturing, focuses on predicting the microstructure and properties of 3D-printed parts. We are leveraging a number of capabilities that have been developed at DOE labs over the years so that we can capture all of the physics involved in simulations of these additively manufactured parts.

Is there a specific quality about Frontier that is attractive for your code?

Turner: The thing that’s really attractive about Frontier is the powerful nodes. Having fewer powerful nodes with a very tightly integrated set of CPUs and GPUs at the node-level gives us the ability to distribute hundreds or thousands of microstructure and property calculations on one or a few nodes across the machine.

What kind of benefit will your project have on people’s lives?

Turner: The biggest visible impact is in cost reduction of additively manufactured parts. Predicting how a part will behave over its lifetime is necessary for the qualification or certification of parts, and we’re trying to get to a place where we can get through that process more quickly and more efficiently.

What is your ultimate goal for exascale?

Turner: Right now, we want to be able to link the process parameters used to produce an additively manufactured part and predict the evolution of the microstructure during a build and the resulting properties. Ultimately, we want to be able to prescribe the process parameters that would create certain properties in a part at specific locations.

UT-Battelle LLC manages Oak Ridge National Laboratory for DOE’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. DOE’s Office of Science is working to address some of the most pressing challenges of our time. For more information, please visit https://science.energy.gov.