High-temperature alloys, often used in power plants and automobile engines, are valued in engineering because they can withstand temperatures that are a high fraction of their melting point. Operating power plants and engines at higher temperatures typically allows for more efficient energy generation, so developing higher temperature alloys is desirable. However, improvement of alloy temperature capability has traditionally been slow, risky, and expensive.

A team of scientists and researchers led by Mechanical Properties and Mechanics Group Member Amit Shyam at the US Department of Energy’s (DOE’s) Oak Ridge National Laboratory (ORNL) is exploring the possibilities of designing various high-temperature–capable alloys that will perform at a very high portion of their melting point. The team used the Cray XK7 Titan—the flagship supercomputer of the Oak Ridge Leadership Computing Facility (OLCF)—to run complex, multi-element simulations and discovered that some elements can limit the detrimental effects that high temperature can have on alloy structure and properties. Dongwon Shin of the ORNL Materials Processing and Joining Group is leading the theoretical investigation. The OLCF is a DOE Office of Science User Facility located at ORNL.

“It is well-known that the upper operating temperature determines the performance limit of several energy generation and utilization technologies,” Shyam said. “Our team discovered a mechanism that allows some alloys to retain their mechanical properties to a temperature that is a higher fraction of their melting point than what was previously considered possible.”

Scientists have been developing alloys at ORNL for years, but the slow rates of development can lead to decades of effort. One of the team’s goals is to create processes that decrease the amount of time and cost required to design and deploy new alloys for a variety of high-temperature applications. Leadership-class computers could be an integral part of this accelerated development process.

Pesky precipitates

Much as honey forms crystal precipitates, alloys in high-temperature applications (such as jet or automobile engine parts) contain hard, metal-strengthening precipitates. At high temperatures, however, these precipitates can grow too large, or transform, and lead to poor mechanical properties that can reduce durability.

“Another analogy is that the precipitates are like chocolate chips in a cookie. Larger but fewer precipitates could weaken the material and cause it to fail under the influence of a mechanical stress,” Shyam said. “We want fine chips that are distributed as evenly as possible.”

The team sought to understand how the addition of new solute elements could affect the material at the atomic level. They studied the arrangement of atoms at the interface where the precipitates meet the metal matrix. More stable configurations of atoms at this interface render the precipitate less likely to grow rapidly at elevated temperatures. They found certain solute elements in an alloy can work to prevent precipitates in lightweight alloys from transforming into a detrimental intermetallic phase—a phase that leads to poor mechanical properties and associated loss in durability of the component fabricated from the alloy. Certain elements or combinations of elements exert a positive influence by lowering the system’s energy and stabilizing the interface between the precipitate and the metal combination.

The scientists first discovered this mechanism in a project funded by the DOE Office of Energy Efficiency and Renewable Energy’s (EERE’s) Vehicle Technologies Office, Propulsion Materials Program, in which they partnered with a major US automaker and that automaker’s engine casting supplier to develop new alloys for potential use in automobiles. The team developed lightweight, higher-temperature alloys for crucial engine parts.

“We are looking at alloys for automobile engine components that are both important and challenging,” Shyam said. “We need good castability, and we also need good thermal properties and mechanical properties over a range of temperatures.”

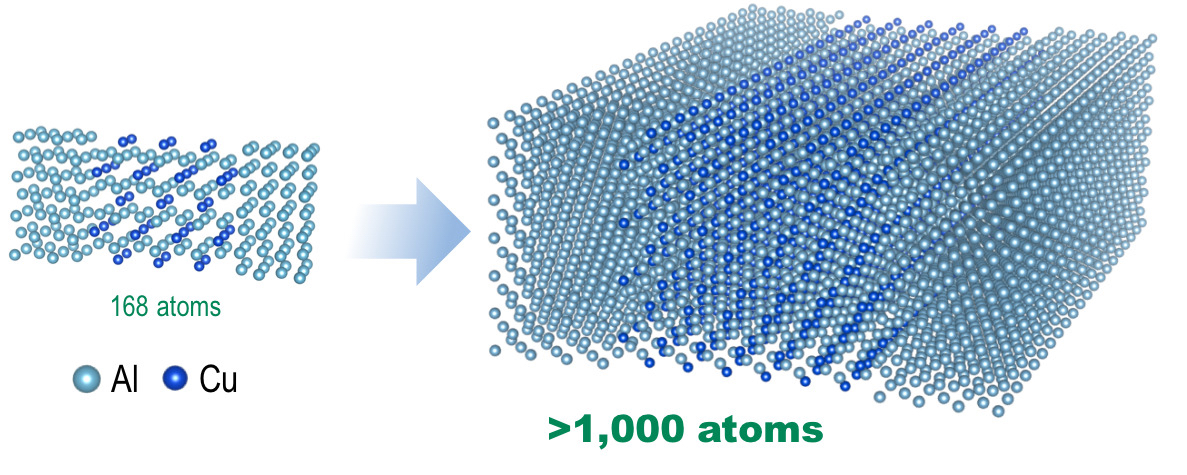

Using Titan, a supercomputer capable of 27 petaflops, the researchers performed density functional theory (DFT) simulations on the Vienna Ab Initio Simulation Package (VASP), a quantum mechanics molecular dynamics package, to look for the best combinations of solutes for the EERE project. They ran several hundred 108- and 168-atom “supercell” simulations of differing element combinations. Supercell simulations contain enough atoms to capture the physics behind atomic configurations without consuming unnecessary computing time.

The team then created a large segregation energy database, which describes the properties that make combinations of elements more or less stable at the interface. Shin said these daunting simulations may have taken up to several months on regular high-performance computers that perform calculations serially, or one at a time.

“The OLCF’s Titan allowed the creation of single ensemble jobs so that these large simulations could be finished within 2 weeks,” he said. “Titan’s unique job scheduling architecture allowed the team to focus on the science.”

The team applied its discoveries to develop an aluminum–copper alloy with the combined benefits of outstanding mechanical properties beyond 300°C and exceptional casting behavior, which makes it ideal for next-generation automotive cylinder heads.

Alloys for the future

Shyam, Shin, and their colleagues are now working on a more open-ended project to explore possibilities for accelerating the development of new alloys. Supported jointly by ORNL’s Laboratory Directed Research and Development program and the OLCF’s Director’s Discretionary program, the team will run larger simulations and then create a new alloy map based on the findings for various solute elements, generating a list of candidate high-temperature materials.

“We are trying to open a new chapter of physical metallurgy for higher-temperature alloys,” Shin said. “If we can use Titan to identify more of these alloying elements and their complex synergistic interaction with precipitate phases, we can expand this concept and design new materials that could have applications in power plants, aerospace, and beyond.”

The team hopes to come up with an atomic model for DFT that will aid in the identification of the best element combinations. Simulating the addition of one new solute element, Shin said, requires 20 individual supercell simulations.

“We are trying to identify elements that complement each other in the alloy,” Shyam said. “You can think of it as pairing wine and foods. Certain wines enhance the flavor of certain foods just like certain metals will arrange themselves into configurations that are more stable at elevated temperatures.”

The researchers completed preliminary simulations on Titan last year using DFT on the GPU-accelerated version of VASP, which enabled them to use 2,000 of Titan’s GPUs for 500 simultaneous 108- and 168-atom supercell calculations. They beta tested the GPU-accelerated version of VASP in early 2016 and became the first researchers to demonstrate its use for a large system in 2017. They also plan to use VASP for other simulations, projecting to use approximately 50 percent of Titan for each large simulation.

The scientists are striving to change the paradigm for current alloy design and shorten what is often a multidecade development and deployment process to significantly less than a decade. The OLCF’s next-generation Summit supercomputer, Shin said, will greatly impact their work.

“A unique feature of the OLCF is that priority is given to larger projects,” Shin said. “With faster computers, we will be able to run even larger simulations in much shorter periods of time. With Titan, what once took decades might now take only a couple years. With Summit, the possibilities are virtually limitless.”

Oak Ridge National Laboratory is supported by the US Department of Energy’s Office of Science. The single largest supporter of basic research in the physical sciences in the United States, the Office of Science is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.