Research may fuel low-temperature combustion technology to save energy, cut emissions

To flip an old saying, where there’s fire, there’s smoke. No one knows that better than Jacqueline Chen, a mechanical engineer at Sandia National Laboratories (SNL) who employs some of the world’s fastest supercomputers to model combustion.

With mechanical engineer Chun Sang Yoo at SNL in California and computational scientist Ramanan Sankaran at the National Center for Computational Sciences (NCCS) in Tennessee, Chen used the Cray XT4 Jaguar supercomputer at the NCCS to generate 35 terabytes (trillion bytes) of data about flames similar to those occurring during ignition and stabilization of diesel-engine jets. That’s more than three times as much data as contained in the printed contents of the U.S. Library of Congress. In their simulation, the researchers burned the simplest fuel—hydrogen molecules. Hydrocarbon fuels, which contain hydrogen and carbon, are more complex, from the relatively simple methane and ethylene to complex gasoline and diesel fuels.

Engineers are using Chen’s data library to develop predictive models to optimize designs for diesel engines and industrial boilers with reduced emissions and increased efficiency. Diesel fuel powers most semitrucks; delivery vehicles; buses; trains; boats; and farm, construction, and military vehicles and equipment in the United States, so development of advanced diesel technology is a leading near-term option by which the country could reduce its fuel consumption and greenhouse gas emissions.

“If low-temperature compression ignition systems employing lean, dilute fuel mixtures make their way into next-generation autos, fuel efficiency could increase by as much as 25 to 50 percent,” Chen says. That also means meeting future low-emission vehicle standards with almost undetectable emissions of nitrogen oxide, a major contributor to smog, she adds.

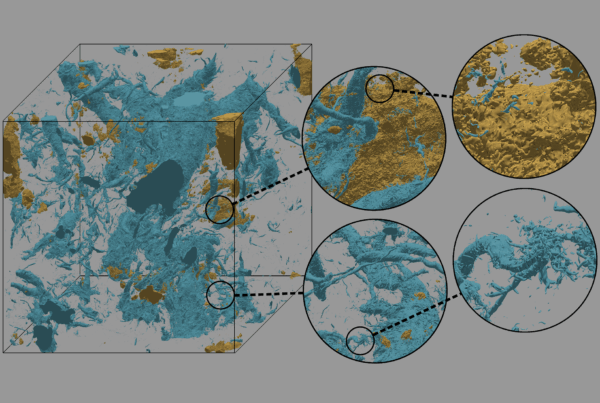

Chen, Yoo, and Sankaran created the first three-dimensional simulation that fully resolves flame features such as chemical composition, temperature profile, and flow characteristics. The model shows feature detail on all size scales—the biggest, the smallest, and everything in between—of a turbulent fuel jet in a hot co-flowing airstream as it ignites.

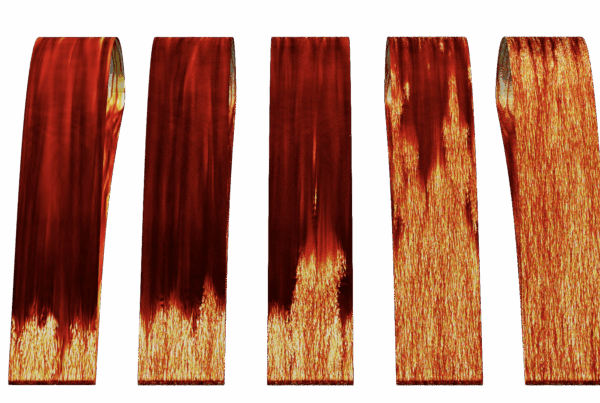

The researchers modeled in unprecedented detail what happens in the so-called “lifted flames” relevant to industrial boilers and diesel engines. Unlike spark-plug ignition systems in automobiles powered by gasoline in which the fuel and oxidizer (air) are premixed, diesel-injection systems have the diesel fuel entering the engine full of hot air via jet nozzles. Turbulence mixes the fuel and air. Pistons subject the air/fuel mixture to pressure, and the mixture heats further, spurring a chemical pathway that sharply increases the concentration of a highly reactive chemical, hydroperoxyl radical, Chen says. The hydroperoxyl radical produces heat that spurs the production of other radicals. At about 1,520 degrees Fahrenheit, the fuel/air mixture auto-ignites, or bursts into flame, as a result of the rapid, heat-producing oxidation of its own constituents, regardless of heat from external sources. This process creates a lifted flame. The temperature peaks around 3,140 degrees Fahrenheit.

“Auto-ignition is helpful because it stabilizes the flame,” Chen says. “A high-temperature flame base supports its existence.”

Before this work by Chen and her colleagues, scientists had modeled only large eddies, or turbulent curlicues, in a burning fuel. They had not simulated the full range of scales down to the smallest eddies, which dictate the viscosity of the system and dissipate heat. Now researchers can resolve the nitty-gritty of the small eddies responsible for flame extinction and reignition.

The Department of Energy (DOE) Office of Basic Energy Sciences and DOE Scientific Discovery through Advanced Computing (SciDAC) program supported the work at SNL. The DOE Office of Science supported the work at the NCCS, located at DOE’s Oak Ridge National Laboratory, through its Innovative and Novel Computational Impact on Theory and Experiment (INCITE) program. INCITE grants huge allocations of supercomputing time to a handful of scientists addressing grand challenges in physics, chemistry, biology, and beyond. The program is unique in providing Ph.D.-level computational scientists, such as Sankaran, to optimize tools, help with data analysis, improve algorithms, and aid in other ways so researchers get the most out of high-performance computers.